PWM Setup

PWM Settings

A HIGHER duty cycle, will mean that the ECU wants the valve to close the turbo wastegate, thus forcing exhaust gases to the exhaust turbine, creating more boost. A LOWER duty cycle will mean that the ECU doesnt want to see more boost as per the mapping instructions.

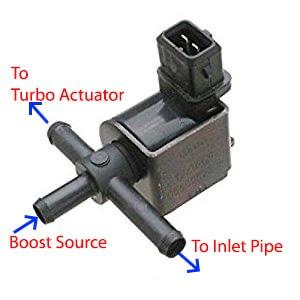

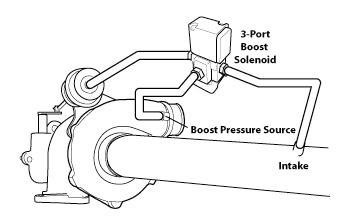

If you look at a typical valve solenoid you will see that it has 3 ports and a 2 pin electrical connection. Also on the valve are 3 ports. 1: This is the atmosphere port which returns any boost pressure bled off back into the cars intake system to be re-used).

2: goes to the turbo’s actuator. This controls the wastegate in the turbo to bleed exhaust gases off depending how much boost the ECU is requesting. 3: goes to a BOOST source. This cannot be a boost/vacuum source as you would find under the inlet manifold post throttle body. The best place for this is the charge pipe straight off the turbo, or the compressor housing itself.

Example valves:

Bosch N75:

MAC valve 3 port:

*add 5151 to ic16 to use A17 are +12v PWM and a ground like A23 wired to the valve or solenoid.

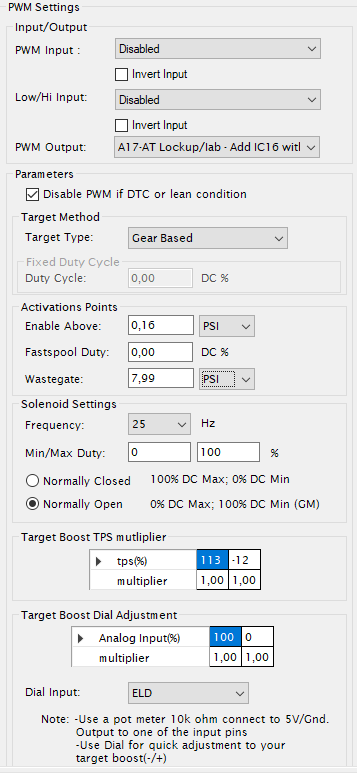

Select Target Type:

Fixed: sets the duty cyle to a fixed duty cyle.

Gear Based: uses the Target Table

RPM Based: uses the Target Table

Activation Points:

Enable above: pressure at wich you want to start using the PWM output / solenoid ( so its not always powered or using current when ideling etc ).

Fastspool* Duty : depending on NC or NO soleniod set the duty cycle that keeps the solenoid closed as long as possible

Wastegate: set to a value near the spring rate of your wastegate -1 PSI

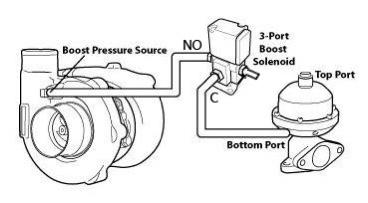

Fastspool

Fast spool feeds the boost back onto the top of the waste gate to keep it sealed. Usually with like a 10psi spring it will start to crack open off the seat slightly around 3psi then spool speed slows down. That keeps it firmly planted until 10psi. enable point you set like 0.2psi so solenoid isnt always running. There are no common values since every ones setup is different. You need to come up with your values using set duty cycles. Then you know what duty cycle = what boost and you can fill in the targets table.

Solenoid Settings:

check manufacturer for fequency and other settings:

Bosch N75 valves are 25hz most MAC valves are either 40 or 50hz ( check your valve )

Next setup the targets table if boost by gear or boost by RPM is used.